Ball valves are a stopcock mechanism that are mainly used to shut off, distribute and change the direction of the medium flow in a pipeline.Like plug or plug valves, they make a 90º turn with the plug to open or close the passage. It is considered a type of ON/OFF valve such as gate, globe, plug, butterfly or check valves.

It is characterised mainly by the fact that in the parts of a ball valve, the regulating mechanism inside is in the form of a perforated sphere. They are practically indispensable components in those industries which have to allow the passage of any fluid (whether liquids, gases or solids).

These elements, thanks to their capabilities, operational benefits and versatility of application, have had a major impact on the productivity and safety of industrial lines. Thus, it becomes an indispensable product for an infinite number of processes.

Parts of a ball valve

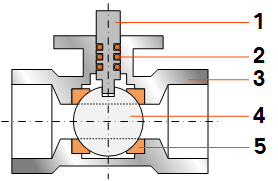

A ball valve has 7 essential parts that make up its structure:

- Body and cover (3): These are the pressure retaining parts, being the container for the internal parts of the valves. The body is where all the parts are assembled.

- Ball (4): It is the element located in the flow passage that allows (or prevents) the flow inside the line, through a 90º turn on an axis perpendicular to the flow direction.

- Stem (1): This is the element that actuates the ball, and can be manually or automatically operated (electrically or pneumatically).

- Handle: This is the lever that allows the ball to be operated through the stem.

- Seats (5): These components, made of different materials, are positioned to hold the ball between the sealing surfaces of the seat itself, thus allowing the fluid to be hermetically sealed.

- Body seals: These are the elements that prevent fluid leakage to the outside between the body and the valve cover. They can be made of various materials.

- Valve stem seals (2): Valve stem seals are the sealing elements that are placed between the valve body and the valve stem to prevent leakage of fluid to the outside. They can be made of different materials.

Operation of ball valves

To understand how ball valves work, it is important to understand the parts of the valve discussed above, as well as the two types of operation.

Ball valves are opened by turning the shaft attached to the perforated sphere or ball in such a way as to allow the fluid to pass through when the perforation is aligned with the inlet and outlet of the valve. When the valve is closed, the orifice will be perpendicular to the inlet and outlet. The position of the actuating handle indicates the valve status (open or closed).

A valve can have two, three or even four ports (2-way, 3-way or even 4-way ball valves). However, most valves are 2-way valves and are manually operated with a lever.

3-way ball valves have an L-shaped or T-shaped orifice, which affect the operation of the circuit (flow direction). As a result, various circuit functions, such as flow distribution or flow mixing, can be achieved.

Advantages of ball valves

Durability

Ball valves are known for their ability to operate smoothly under regular maintenance.

Easy maintenance

Under favourable conditions, a single ball valve can operate for many years. Fixing them is usually inexpensive because replacements are readily available.

Easy-to-operate mechanism

The design allows for easy installation and repair and facilitates operation without having to worry about side loads, which is often a problem with other types of valves.

Efficiency

Ball valves are leak-proof and open and close at high speed, making them the best choice for emergency operations.

Design

Their adaptability of design also makes them an affordable option. Ball valves are worth the investment as they are durable and functional for many years. In addition, ball valves allow for soft-seated valve designs and metal-to-metal ball valves, among others.

As can be seen, ball valves offer excellent sealing, easy maintenance and low pressure loss in relation to the size of the ball orifice.

From FHT, manufacturers of ball valves, we hope that this post has clarified your doubts about the parts of a ball valve and its operation. Discover our wide range of ball valves catalogue and some of our products such as bronze ball valves or tank bottom valves.