Ball valves are fundamental devices in the field of industry and fluid transport. Within this broad category, V-passage ball valves stand out for their distinctive design and functionality. In this article, we will explain in detail the features and advantages of these valves, as well as their applications in various fields.

What are V-pass ball valves?

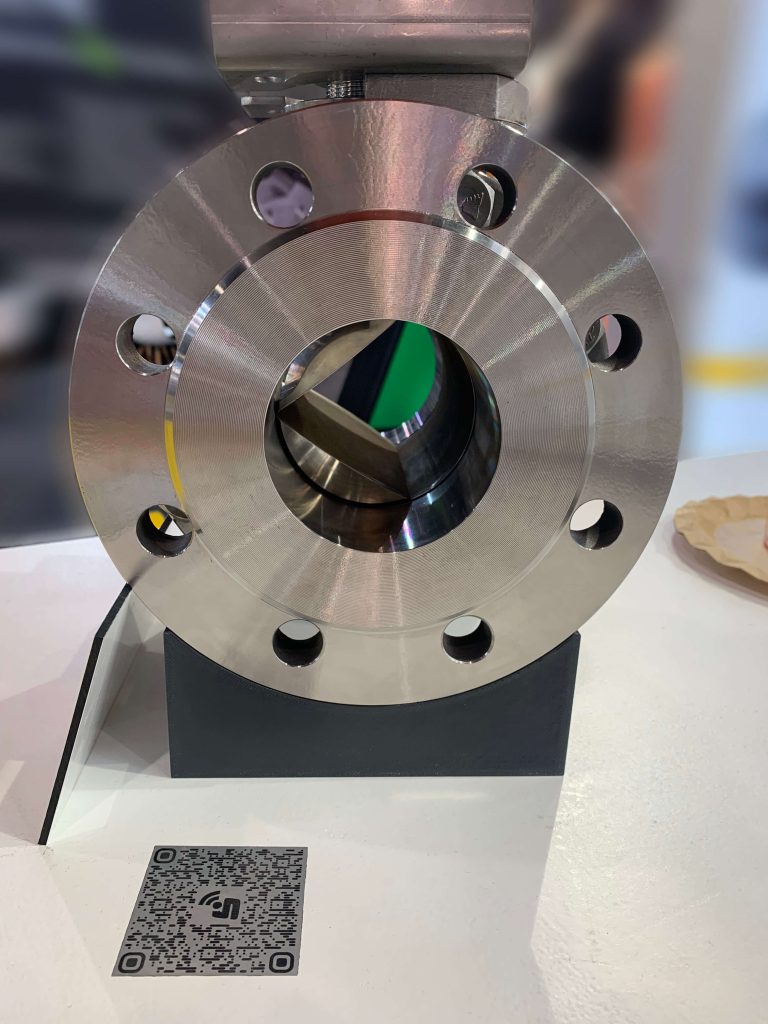

V-port ball valves are flow control or regulating devices characterized by their V-shaped closing mechanism. Their internal structure consists of a V-shaped perforated ball, the ball, when rotated 90 degrees, allows or blocks the passage of fluid through the valve.

Features and design of V-port valves

V-pattern ball valves have several distinctive features:

Robust design: These valves are designed to withstand high pressures and temperatures, making them suitable for a wide range of industrial applications.

Hermetic sealing mechanism: These ball valves provide a completely tight seal in the contact area between the ball and seat. This ensures precise flow control and prevents unwanted leakage.

Low pressure loss: The V-geometry of these valves minimizes pressure loss compared to other valve types. This results in improved energy efficiency and reduced load on pumping systems.

Advantages and applications

V-port ball valves offer several significant advantages in a variety of applications:

a) Precise flow control: Thanks to their ball shut-off mechanism, these valves allow highly accurate control of fluid flow. This is especially important in applications where precise flow regulation is required, such as in water distribution systems or in sensitive industrial processes. In addition, their high configurability (15º, 30º, 60º and 90º) offers a wide range of possibilities for different applications.

b) High resistance to clogging: The V-shaped geometry of these valves minimizes the accumulation of sediments and solid particles in the closing area, which reduces the possibility of clogging and guarantees reliable long-term operation.

c) Versatility in use: V-Port ball valves are used in a wide variety of industrial applications, from heating and ventilation systems to chemical plants and refineries. Their robust design and ability to withstand extreme conditions make them a popular choice in many industries.

Installation and maintenance considerations

When installing and maintaining V-port ball valves, it is important to consider some key factors:

Proper material selection: Depending on the type of fluid and operating conditions, compatible materials should be chosen for the main parts of the valve, such as the ball, the seat (can be soft or metal-to-metal) and the body. This ensures optimum resistance to corrosion and erosion.

Inspection: When suspended particles are present and to prevent sediment accumulation and ensure optimum performance, V-pass ball valves should be inspected periodically. This is especially important in applications where the conveyed fluids may contain impurities or debris.

Innovations and advances in V bore ball valves

Over the years, V-port ball valves have undergone significant advances in terms of design and technology. These innovations have further improved their performance and broadened their applicability in various industries. Some of the most notable advances include:

Advanced materials of construction: Manufacturers have developed stronger and more durable materials for the main parts of V-port ball valves. These materials include high-grade stainless steel, all alloys and coatings, which provide increased resistance to corrosion and erosion.

Improved sealing technology: The seals and packings used in V-ball valves have undergone significant improvements. High-quality seats have been developed, such as O-rings and seats made of RPTFE, DEVLON or PEEK depending on the need and process, this provides even more reliable sealing and reduce leakage to a minimum.

Automation and intelligent control: V-pass ball valves can now be equipped with electric or pneumatic actuators, allowing for automated operation and more precise flow control. In addition, the integration of intelligent control systems and digital communication has optimized the remote monitoring and control capability of these valves.

Modular and customized designs: FHT Valves offers custom and customized design options to suit the specific needs of users. This includes the ability to select the degree of V-port, different sizes and materials, connections and additional features.

V-Port ball valves are an efficient and versatile solution for flow control in a variety of industrial applications. Their robust design, tight shutoff mechanism and low pressure loss coefficient make them a reliable and effective choice. In addition, advances in materials, technology and design have further improved their performance, durability and automation capabilities.

Importantly, FHT Valves stands out among V-shaped ball valve manufacturers for its excellence and expertise in the field. Its commitment to quality and innovation is reflected in the incorporation of advanced materials of construction, improved sealing technology and custom designs. In addition, FHT Valves has responded to environmental and safety demands by complying with regulations and developing leak detection and monitoring systems.

V-port ball valves, such as those offered by FHT Valves, are a reliable choice for flow control in a variety of industrial applications. Their ability to provide precise flow control, resist clogging and adapt to specific user needs make them a preferred choice. Backed by advances in technology and a focus on sustainability, these valves continue to be an efficient and environmentally friendly solution.

Rely on FHT Valves’ V-port ball valves to ensure optimum performance and increased efficiency in your flow control systems.