Hydrogen is gaining a leading role in the transition to a cleaner and more sustainable industry. This renewable energy has become an essential fuel in sectors such as energy, mobility and the chemical industry. As the demand for hydrogen-based solutions grows, so does the need to manufacture specialized components that can work with this feedstock, such as ball valves, which have to be specifically designed to handle the demands of this gas.

Why is hydrogen used in industry?

Hydrogen is valued primarily for being a clean and sustainable energy carrier. Through the process of water electrolysis, green hydrogen can be produced, a promising alternative to fossil fuels. However, hydrogen is still a gas and as such requires safe handling through equipment designed for it, as it is a highly flammable and reactive gas. In this context, ball valves for hydrogen ensure safe gas handling in industrial environments.

Characteristics of hydrogen ball valves

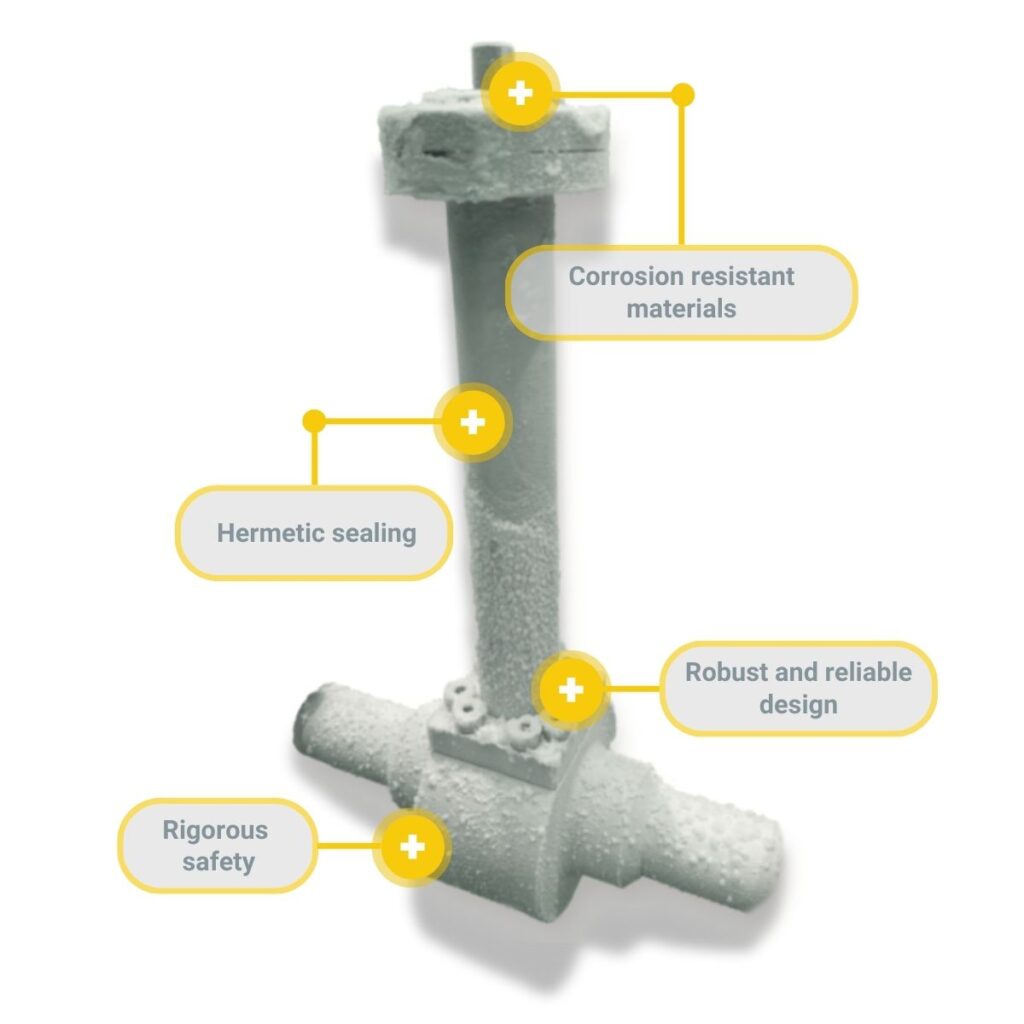

Hydrogen ball valves are the “workhorses” of the hydrogen industry. in the hydrogen industry; they are designed to safely control the flow of hydrogen gas. Unlike standard ball valves, these valves are manufactured from hydrogen-compatible materials, preventing degradation and long-term hardening. In addition, to maximize safety, they often incorporate special seals and gaskets that minimize leakage, a critical attribute given that hydrogen is a volatile gas. Due to the unique properties of hydrogen, these valves must meet certain requirements:

- Corrosion resistant materials

Hydrogen can react negatively with certain materials, causing phenomena such as embrittlement, which weakens metals. For this reason, hydrogen ball valves must be made of highly corrosion-resistant materials. - Hermetic sealing

Because hydrogen is an extremely small molecule, the risk of leakage increases if sealing is inadequate. Therefore, these valves must have advanced sealing systems, such as special gaskets and packing, which ensure a tight seal and minimize the chances of leakage. - Robust and reliable design

The design of the ball valves must be prepared to withstand high pressures and temperatures, common conditions in hydrogen systems. - Rigorous safety testing

Given the risk of explosion associated with hydrogen leaks, valves must undergo rigorous testing to validate their ability to handle the gas safely, thus ensuring their reliability in critical and volatile contexts, such as gas transport.

With the increasing use of hydrogen in various industries, hydrogen ball valves play an important role in ensuring the safe and efficient handling of this gas. From their material selection to extensive safety testing, every element of their design is optimized to meet the unique demands of hydrogen use.

At FHT Valves, we are committed to offering customized ball valve solutions that meet quality and safety standards for various industrial sectors.