BALL VALVES

CAVITY FILLER

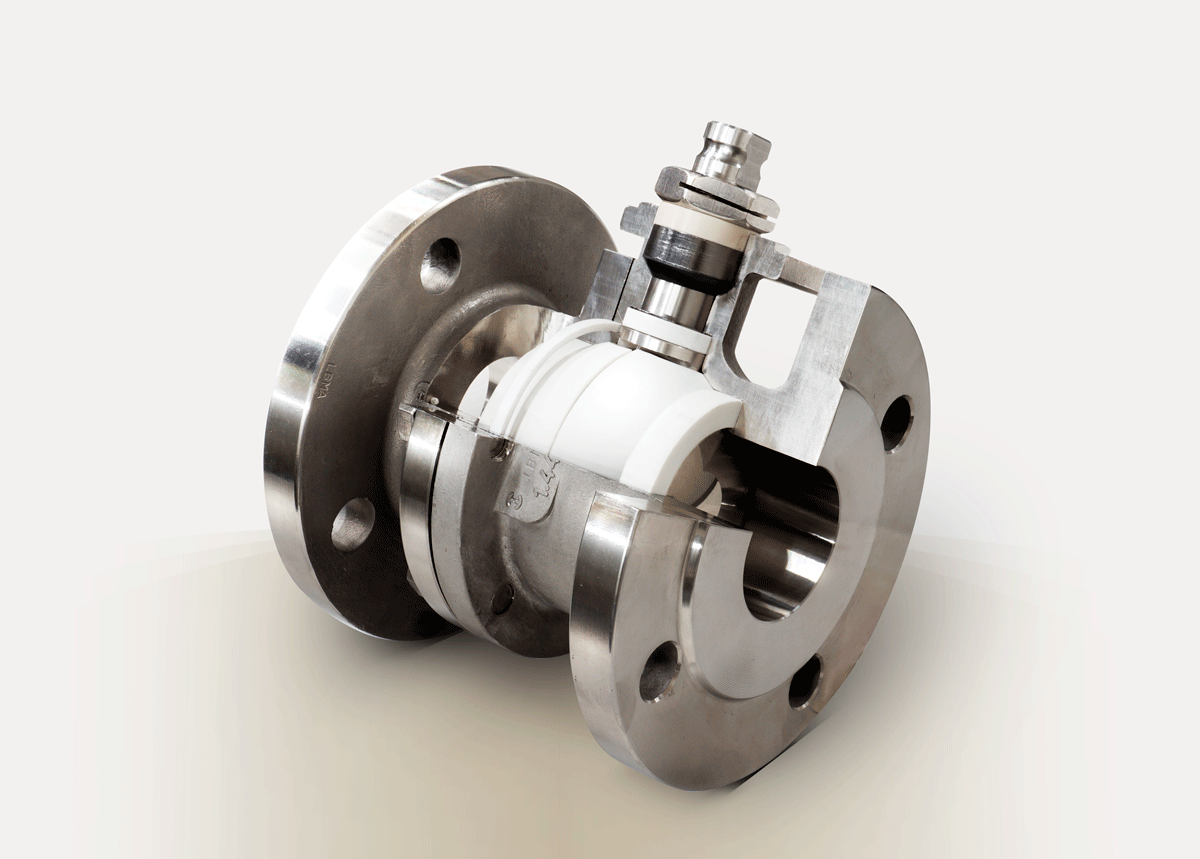

CAVITY FILLER BALL VALVES

Free from uncoated spaces for clean industries

Usual ball valves allow fluids and debris to remain in the inner body cavity, which is almost impossible to clean. Cavity Filler Ball valves are also the perfect solution even in industrial sectors where products prone to fouling must be transported to prevent the accumulation of residues and the proliferation of germs and bacteria.

Highly configurable valves available in 2-way and 3-way bodies and can even be supplied with a V-ball for flow control.

HYGIENIC RESPONSE

FOR PHARMACEUTICAL AND FOOD INDUSTRIES

Designed for food & beverage

The ball valves of FHT valves are specifically designed for solids have an integral seat that occupies the space around the ball, avoiding the possibility of accumulation of pollutants.

It offers excellent performance in pharmaceuticals, food and beverages, micro cooking and other healthcare systems.

A common and serious problem

The process of products ranging from reactive monomers such as styrene and butadiene to starches and sludge, tend to polymerize or ferment within the cavities within the valves. They can also damage the seat surface and even block the valve shutter. To avoid possible damage and abrasions in the integral seats we manufacture them as standard in Fiberglass or with load of STAINLESS STEEL.

Anti-torsion stem manufacturing in DUPLEX

Another advantage of FHT Cavity Filler ball valves is that the stem is made of DUPLEX to prevent twisting.

This integral seat possibility is availableThis integral seat possibility is availableeven in our Tank Bottom valve design.

FEATURES AND ADVANTAGES

SIZES

FROM 1/2′′ (DN15)

UP TO 8′′ (DN200)

in full bore design to allow a better flow and prevent clogging.

RATING

FROM CLASS 150 (PN16)

UP TO CLASS 2500 (PN420)

to meet the needs of any industry.

SEATS

PTFE, RPTFE, DEVLON, PEEK…

to meet the needs of any industry.

LOCKING DEVICE OPTIONAL

To avoid unintentional openings

CLOSURE

Available in manual and actuated

EASY MAINTENANCE

Simple care for a worry-free experience

ASK FOR FURTHER INFORMATION

Do not hesitate, we solve any doubt and quote any order.

We will respond in less than 24 hours.

PRODUCTION RANGE

PRODUCT CERTIFICATES

In addition to general certifications, Cavity Filler Ball Valves have their own product certifications.

| TA - Luft | Tightness of stems for gas emissions Estanqueidad de los vástagos para las emisiones de gases |

| SIL | Capacity SIL 3 EN 61508:2010 for floating and Trunnion Capacidad SIL 3 EN 61508:2010 para flotantes y guiadas |

| ATEX | European Directive 2014/34/EC Directiva Europea 2014/34/EC |

| ISO 15484-1 | Fugitive emission test according to ISO 15848-1:2006 Ensayo de emisiones fugitivas según ISO 15848-1:2006 |

| FIRE SAFE | BS 6755 / EN-ISO 10497 / API 607 |

| AD 2000 MERKBLATT | AD 2000 MERKBLATT W 0 / A 4 |

| MONOGRAMA API | STANDARD API 6D - 0613 |

| CE 0036 | Module H, Design, Manufacturing and Sales Módulo H, Diseño, fabricación y venta |