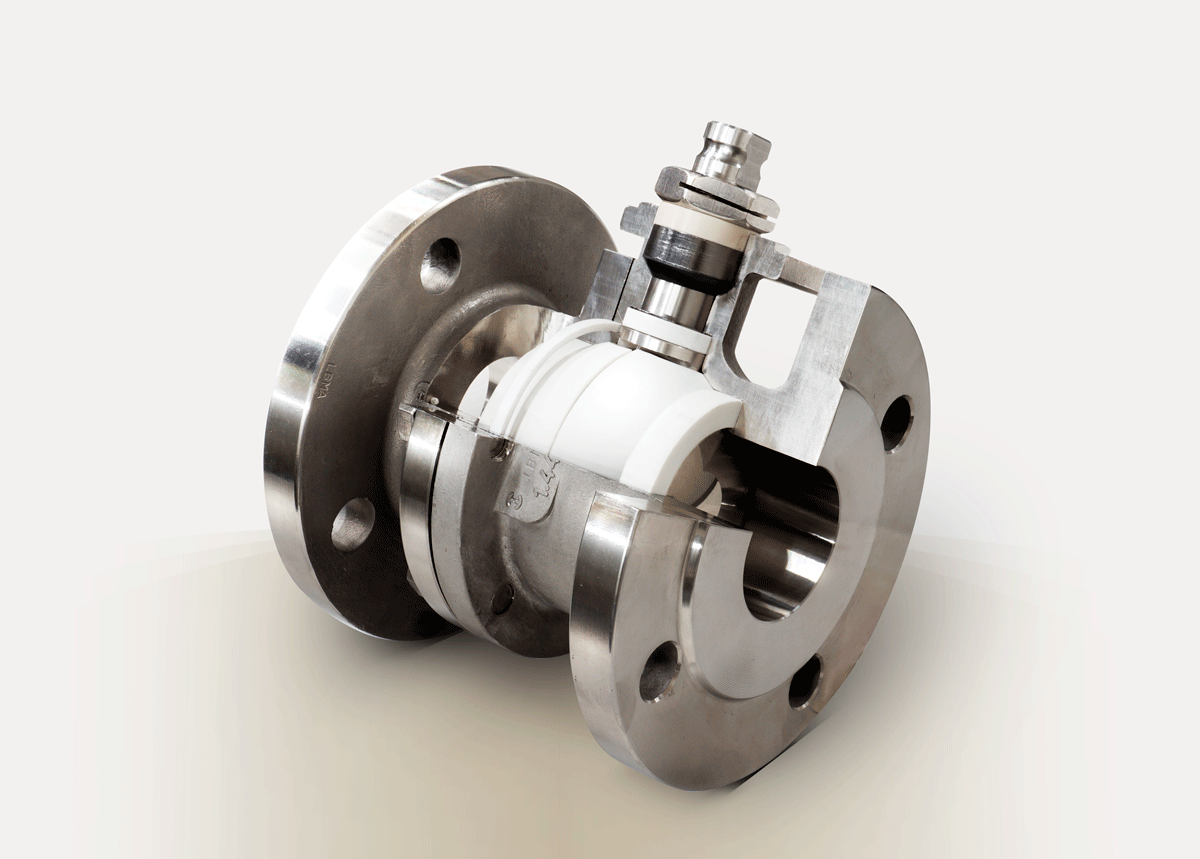

Cavity filler ball valves are one of the most essential components in flow control systems across various industries. These ball valves provide an efficient solution for handling fluids, from oil and gas to water treatment and other industrial processes.

What Are Cavity Filler Ball Valves?

A cavity filler ball valve is a type of ball valve where the seats (the sealing surfaces of the valve) are integrated directly into the valve body, eliminating the need for additional components such as seat rings. This simplified design reduces the number of parts and improves reliability by removing potential leakage points between moving parts and the valve body.

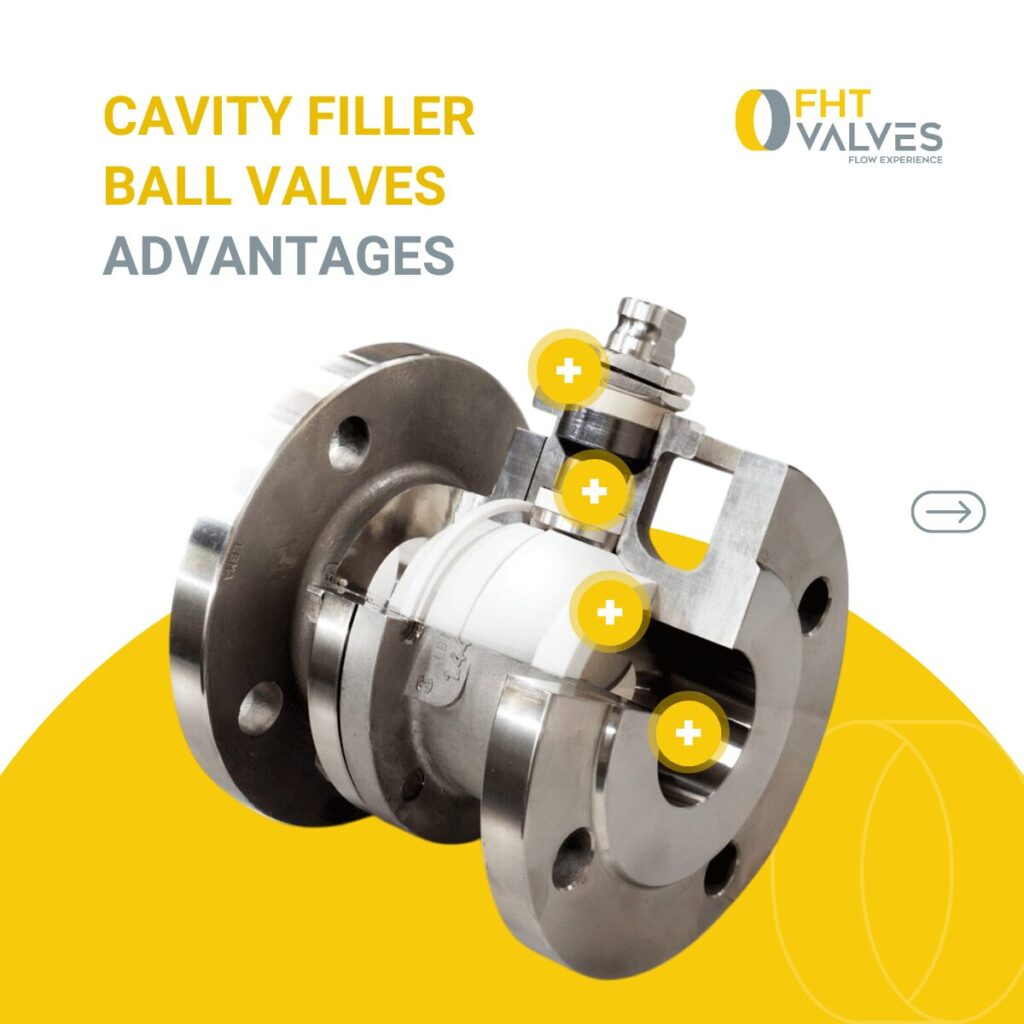

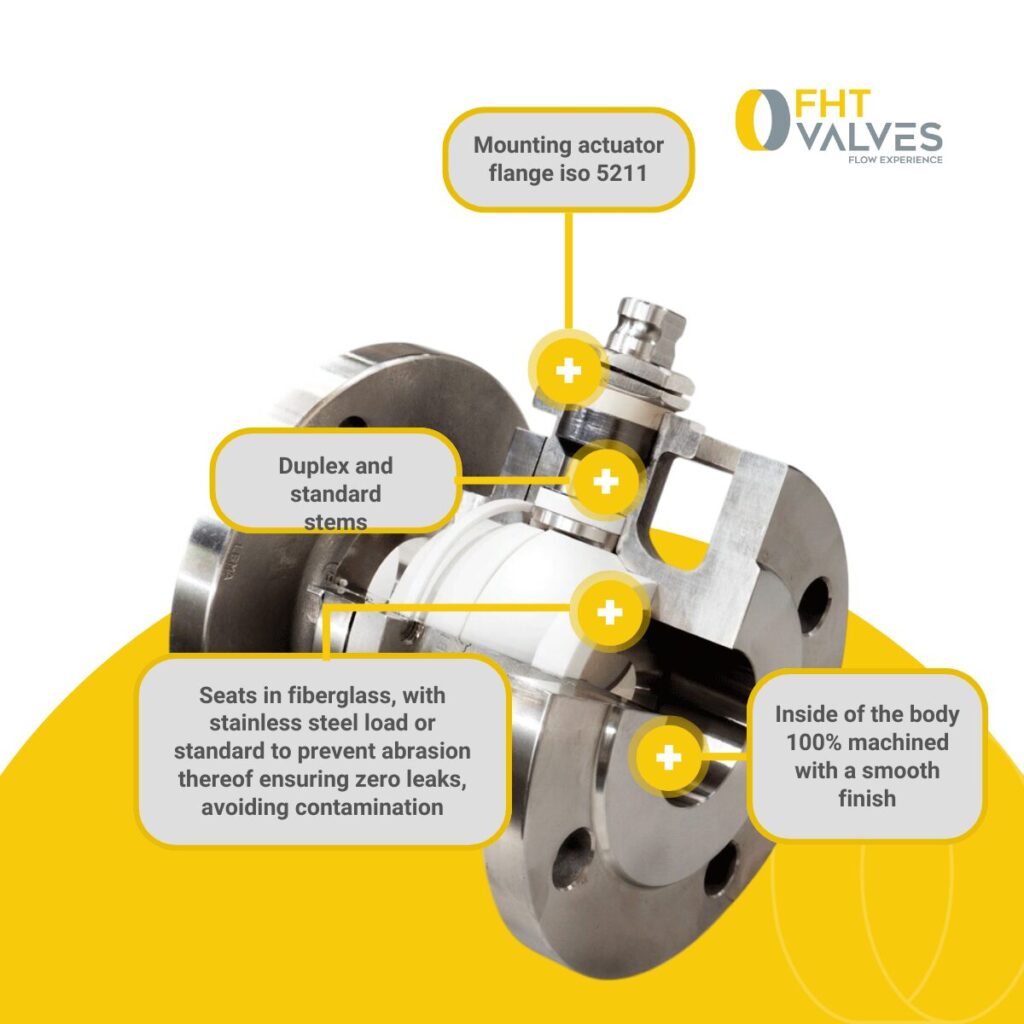

Features and Advantages of Cavity Filler Ball Valves

- Available in sizes ranging from 1/2” (DN15) to 8” (DN200) with full bore, ensuring optimal flow and preventing obstructions.

- Can be operated manually or with an actuator for greater versatility.

- Pressure ratings range from Class 150 (PN16) to Class 2500 (PN420), adapting to the demands of various industries.

- Optional locking mechanism to prevent accidental openings and enhance operational safety.

- Seat materials available in PTFE, RPTFE, DEVLON, and PEEK, meeting diverse application requirements.

- Easy maintenance and optimized design for effortless cleaning and extended service life.

- Anti-Torsion DUPLEX construction, preventing deformations and ensuring optimal performance under demanding conditions.

Where Are Cavity Filler Ball Valves Used?

Standard ball valves allow fluids and debris to accumulate in the internal cavity, making them difficult to clean. Our dead-space-free valves are designed to prevent residue buildup, minimizing the risk of bacterial growth. This makes them the ideal solution for industries handling fluids prone to deposit formation or those requiring strict hygiene standards.

Industries that benefit the most from these valves include:

- Pharmaceutical Industry: Precision and safety are crucial, as products require strict control and sterility conditions. The one-piece design simplifies maintenance and reduces contamination risks, making these valves ideal for pharmaceutical production.

- Food Industry: In food processing, cavity filler ball valves are the preferred choice due to their ability to handle fluids of varying viscosities and temperatures without compromising product quality. They are particularly suitable for juice, dairy, and sauce production. Their easy-to-clean design and corrosion-resistant materials ensure compliance with stringent food safety and hygiene regulations.

Why Choose Our Cavity Filler Ball Valves?

At FHT Valves, we manufacture high-quality cavity filler ball valves designed to meet the most demanding customer requirements. Our valves are made from premium materials and comply with international standards, ensuring long-term durability and reliable performance.