In the world of industry and engineering, the selection of the right valves is essential for the efficient and safe operation of a wide range of systems and processes. Two types of valves often found in industrial applications are plug valves and ball valves. While both perform the important task of controlling the flow of liquids and gases, they have notable differences in terms of design, operation and benefits.

In this article, we will delve into these differences and explain why, in many situations, ball valves are the preferred choice of professionals in the field.

What is a Plug Valve?

To understand the differences between plug valves and ball valves, it is essential to begin by defining what a plug valve is. Also known as plug valves, these are all-or-nothing devices that use a cone-shaped disc to regulate the opening and closing of fluid flow. They are widely used in various industrial and domestic applications due to their simplicity and reliability.

Operation of a Plug Valve

The operation of a plug valve is based on a relatively simple design. The control element, which is a cone-shaped disc or wedge, moves perpendicular to the fluid flow. When the disc is fully rotated through 90°, maximum flow is allowed, and when rotated, the fluid flow is shut off. This opening and closing mechanism is achieved by means of a stem that connects to the plug and is operated by a handwheel, lever or motorized actuator, depending on the specific application.

Differences between Plug Valves and Ball Valves

Although plug valves and ball valves share the primary function of regulating fluid flow, they have significant differences that influence their performance and ideal applications. Below, we will explain some of these key differences:

Tap Valve Features and Benefits

Features

Material of Construction: Plug valves are typically manufactured in a variety of materials, such as stainless steel, cast iron and PVC, making them suitable for a wide range of applications and environments.

Longevity: These valves are known for their durability and ability to withstand harsh conditions, such as high pressures and extreme temperatures.

Benefits

Tightness: Plug valves offer excellent sealing, minimizing fluid leakage when fully closed.

Durability: Their rugged construction allows them to operate reliably for long periods without frequent maintenance.

Precise Control: They are ideal for applications where precise and gradual flow control is required.

Now that we have explored the features and benefits of plug valves, it is time to look at ball valves and why many industries prefer them in various applications.

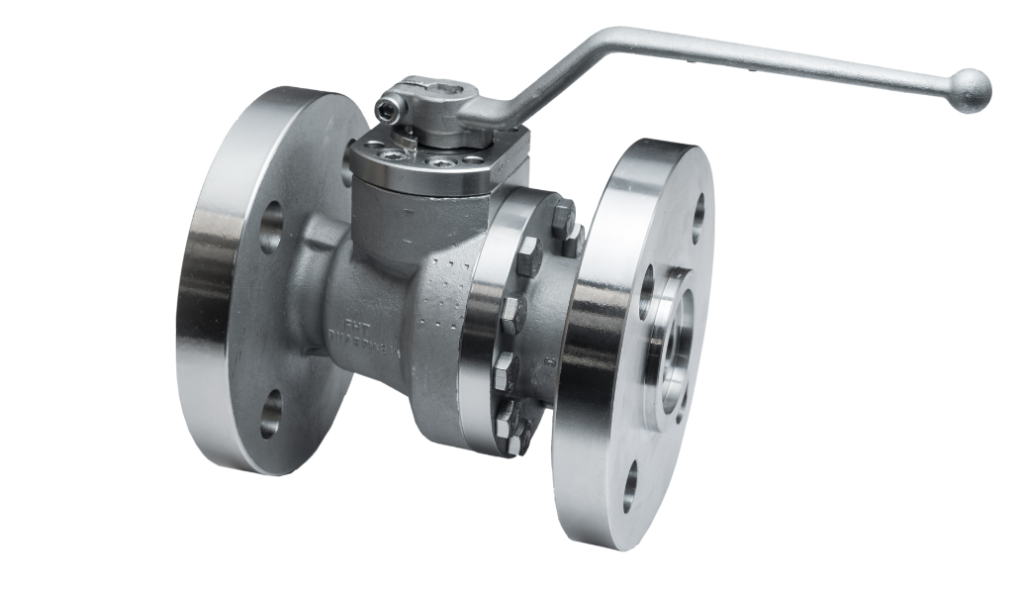

Features and Benefits of Ball Valves

Ball valves, also known as ball valves, feature a distinct design and operating mechanism that significantly differentiates them from plug valves. Let’s take a closer look at their features and benefits:

Features

Material of Construction: Like plug valves, ball valves are manufactured in a variety of materials, from stainless steel to plastic, making them versatile in terms of applications and chemical resistance.

Longevity: Ball valves are designed to resist wear and corrosion, making them a durable choice even in harsh environments.

Types: Ball valves can be full bore, reduced bore, three-way or four-way, allowing for greater flexibility in their use.

Benefits

Fast Opening and Closing: One of the main advantages of ball valves is their ability to open and close quickly, making them ideal for applications requiring instant flow control.

Reliable Sealing: Thanks to their ball design that fits snugly into the seat, ball valves provide a tight seal, minimizing leakage and reducing the risk of contamination.

Low Maintenance: Ball valves often require minimal maintenance due to their robust construction and lack of wear-prone moving parts.

Wide Temperature and Pressure Range: Ball valves can handle a wide range of temperatures and pressures, making them suitable for diverse applications.

Versatility: Their versatile design makes them suitable for a variety of applications, from domestic applications to critical industrial processes.

FHT Valves, Manufacturers of Ball Valves

At FHT Valves, we are a leading manufacturer and supplier of high quality ball valves, and we firmly believe that they are the best choice in many applications. Below, we will explain why we prefer ball valves over plug valves and how our products can benefit your industry.

Why We Prefer Ball Valves

Flow Control Efficiency

Ball valves are unmatched in their ability to provide accurate and fast flow control. Their ball design allows for instant opening and closing, which is essential in applications where precise flow regulation is critical. Whether in potable water systems, chemical processing or industrial piping systems, ball valves offer superior performance.

Hermetic Sealing

At FHT Valves, we understand the importance of maintaining the integrity of your system and preventing costly leaks. Ball valves, with their seated design, ensure a tight seal that minimizes fluid losses. This not only reduces waste of resources, but also contributes to maintaining a safer working environment.

Durability and Low Maintenance

Our ball valves are designed to last. Manufactured with high quality materials and advanced production techniques, they resist wear, corrosion and extreme conditions. This translates into reduced maintenance and extended service life, resulting in significant savings over time.

Versatility in Applications

From heating and cooling systems to critical industrial processes, our ball valves suit a wide range of applications. With options ranging from full bore to three-way valves, we offer versatile solutions that meet the needs of different industries.

Commitment to Quality

At FHT Valves, we pride ourselves on our dedication to quality. Each of our ball valves undergoes rigorous performance and quality testing before leaving our facility. This ensures that our customers receive products that meet the highest standards of excellence.

Although plug valves have their place in certain applications, ball valves offer a number of advantages that make them the preferred choice in many industries. Their flow control efficiency, tight sealing, durability and versatility make them a wise investment to ensure optimum performance of your systems and processes.

At FHT Valves, we are committed to providing the best ball valve solutions to meet our customers’ needs and contribute to the success of their projects.