Valves are essential components in many fluid control systems., from heating and air conditioning systems to industrial plants and water distribution systems.

In industry, there are different types of valves, but two of the most common are regulating valves and on/off valves. In this article, we will explore the features and advantages of each of these valves to better understand their applications and benefits.

Characteristics of the regulating valves

Regulating valves, also known as control valves, are used to adjust and control the flow of fluids or gases in a system. These valves are designed to provide precise control of the amount of flow passing through them.

Unlike on/off valves, regulating valves allow the flow to be adjusted to different levels, making them ideal for situations where precise regulation is required.

- Accuracy and control: Regulating valves are known for their ability to provide precise flow control. This is due to its design and specific features, such as an actuator that allows adjusting the valve opening in different positions. This fine-tuning capability allows the flow to be regulated according to the needs of the system, resulting in more precise and efficient control.

- Flexibility: Regulating valves are highly flexible, as they can be adapted to different operating conditions. They can operate over a wide range of flow rates and pressures, making them suitable for a variety of industrial and commercial applications. In addition, these valves can withstand changes in system load and automatically adjust to maintain the desired flow rate.

- Stability: Due to their precise adjustability, regulating valves offer stability in flow control. They can automatically compensate for pressure and flow fluctuations, thus maintaining a stable output. This is especially important in systems where constant monitoring is required to ensure optimum performance.

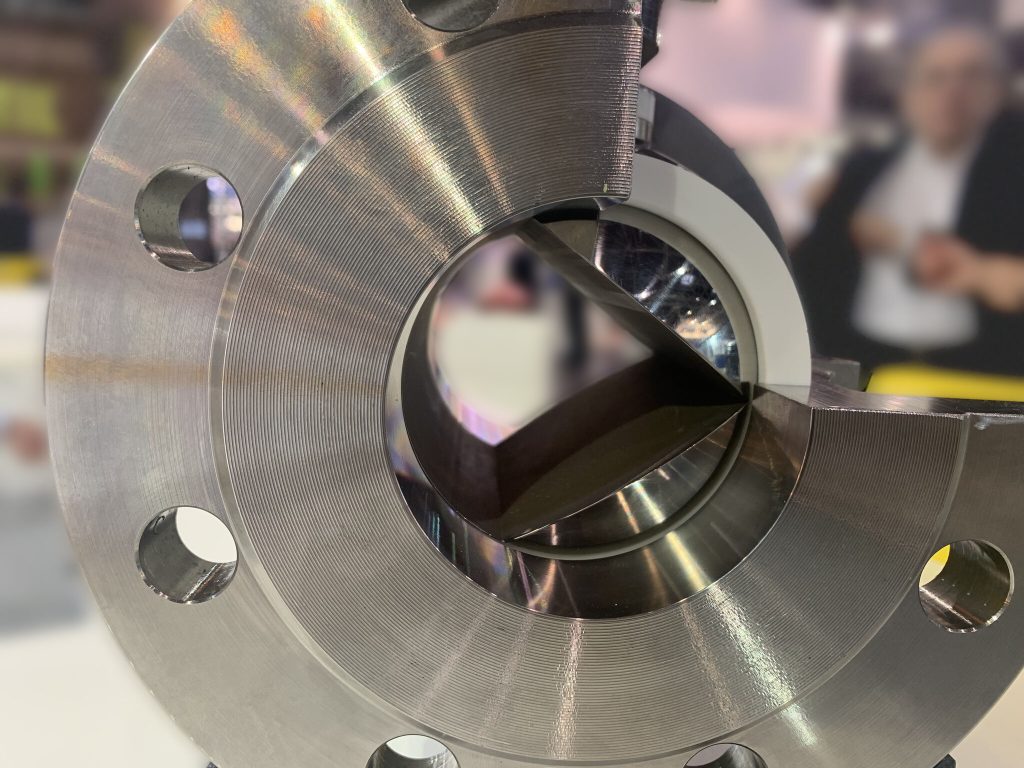

On/off valve characteristics

On/off valves, also known as all-or-nothing valves, are a type of valve that have only two states: fully open or fully closed. These valves are widely used in applications where full flow or complete flow interruption is necessary.

- Simplicity: One of the main advantages of On/off valves is their simplicity. Due to their two-position design, these valves are easy to operate and maintain. They do not require precise adjustments or complicated controls, which simplifies their installation and use in different systems.

- Cost: On/off valves are usually cheaper compared to regulating valves. Since they do not require sophisticated mechanisms for flow control, they are more affordable to manufacture and maintain and are therefore a cost-effective option for applications where precise flow regulation is not required.

- Reliability: Due to their simple design, On/off valves are known for their reliability. Having only two positions, the possibility of failure or leakage is lower compared to more complex regulating valves. This makes them ideal for applications where reliable and safe operation is required.

- Tight shut-off: On/off valves provide tight shut-off when fully closed, preventing leakage or contamination of fluid in the system. This is especially important in applications where hazardous substances are handled or in systems that require precise flow control to avoid losses.

Comparison and proper choice of valves

The choice between control valves and on/off valves depends on the specific needs of the application.. Both types of valves have different advantages and are suitable for different situations.

If precise flow control is required, a regulating valve is the most suitable option. These valves offer precise and stable flow regulation, making them ideal in applications where constant control and fine adjustments are required.

On the other hand, if the application requires simply opening or closing the flow completely, an on/off valve is a more practical option. These valves are easy to operate, cost-effective and reliable in applications where precise flow regulation is not required.

In summary, regulating valves are ideal when precise flow control is needed, while on/off valves are more suitable for applications where simple and reliable operation is required. The correct choice will depend on the specific needs of each system and the importance of flow control.

Conclusion

Both regulating valves and on/off valves play a crucial role in many industrial and commercial applications. Each has its own distinct characteristics and advantages.

Regulating valves offer precise control, flexibility and stability in flow control They are ideal when a precise and constant regulation of the flow of fluids or gases is required.

On the other hand, On/off valves are simple, economical and reliable. They are suitable for applications where only complete opening or closing of the flow is required.

Ultimately, the choice between these valves will depend on the specific needs of each system. It is important to carefully evaluate flow control requirements, operational simplicity and costs before selecting the most suitable valve for a given application.

At FHT Valves, our goal is to provide you with the best advice and support so that you can make the best decision when choosing valves. We understand that proper valve selection is critical to the proper operation of your fluid control systems.

Our team of experts is at your disposal to provide you with detailed information on the features and advantages of different types of valves to help you find the option that best suits your specific needs.

We want to make sure you get the highest quality and performance valves to optimize the efficiency and reliability of your processes. At FHT Valves, we are committed to providing you with reliable valve solutions and meeting your requirements in a comprehensive manner.

If you want to know more about the types of ball valves, you can read in our blog an article about it.